The main specialization of IMI-Polska Sp. z o.o. is the design, integration and construction of machines, devices and production lines in industry.

We create dedicated projects from concept through design to implementation and commissioning.

read moreIndustrial robots and positions

read moreLorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labor.

read moreLorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labor et dolore magna aliqua.

read moreHelp in certifying machines in accordance with the Machinery Directive 2006/42 / EC.

read moreWe make control cabinets, programme PLCs, create HMI visualizations.

read moreOur extensive machine park, consisting of CNC and conventional numerical machine tools, gives great opportunities to produce high-quality parts.

read moreOur engineers can also work for the client directly at his premises.

read moreLorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labor et dolore magna aliqua.

read moreThe design process is divided into six stages:

Customer needs research

Preparation of the offer concept and valuation

Design in a 3D environment, simulations and analyzes, project approval

Production, assembly of the stand and production technology

Validation and FAT (Factory Acceptance Test) at the headquarters of IMI POLSKA

Delivery and commissioning at the customer's site

The satisfaction of our clients is most important to us, therefore we make every effort to ensure that the cooperation is professional and efficient.

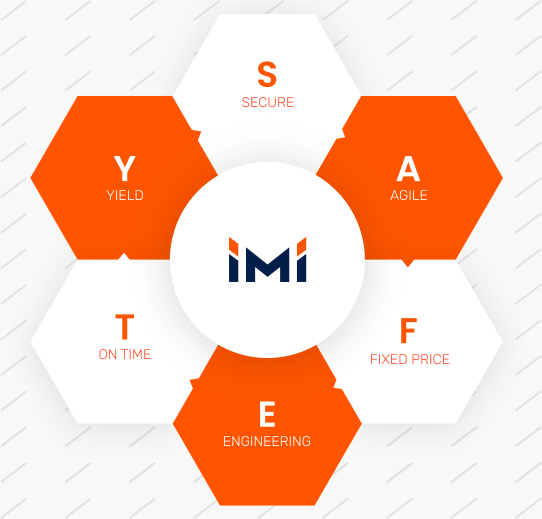

Safety is our priority in our work. It has many dimensions for us, which is why we have created the SAFETY strategy (Secure, Agile, Fixed price, Engineering, on Time, Yield), which guarantees it on all levels of cooperation, not only in the field of machine safety. We believe that this is where our success lies.

We are financially transparent. The analysis by BISNODE assesses our credibility as transaction risk lower than the market average. In 2019, we were awarded the Certificate of Business Credibility by this intelligence agency.

We are a company that works on the basis of the so-called design structure. We have established PMO (Project Management Office) in the company, which is responsible, among others, for: project portfolio management, training of managerial staff, project management, implementing project management methodology in the company and creating methods and standards.

Nobody likes surprises, so we make every effort to ensure that our clients feel safe within the project budget. The principle of a fixed price is a response to the needs of our customers.

Our engineers are constantly trained in the field of machinery safety. We are also a company that carries out machine safety audits in various production plants. As a machine manufacturer, we give the CE mark and issue declarations of conformity based on the applicable EU regulations.

We operate based on the so-called Critical chain method, which is an extension of the standard critical path. We monitor tasks and time buffers along the critical path with the greatest care and understand the limitations involved.

We remember about the profit of our clients at the design stage by analyzing, among others the rate of return on investment (ROI) taking into account the costs of service, inspections or maintenance costs of a given line. We analyze during projects when it is business justified, for example, to use POKA YOKE, SMED solutions or issues related to TPM, such as OEE

IMI-Polska Sp. z o.o. as a supplier of production lines in industry – despite the extensive machinery park – it also uses a number of sub-suppliers.

Machining

press brake bending of sheets

mechanical parts delivery truck

construction of steel structures

thermal cutting

supplier of electrics and automation

We build lasting business relationships with our suppliers. Our internal system of suppliers allows us to evaluate the quality of services offered, timeliness and price and promote the best.